My Business Idea: from Concept to Reality

One idea's journey from being trapped in my brain to being held in my hand.

“People have million-dollar and billion-dollar ideas daily.” - Sarah Blakely, founder of Spanks

The problem is that most ideas stop there, in the realm of ideas.

I’m Zwigs, and I started a company in a desperate attempt to chase the entrepreneurial dream. Every business starts with an idea. This is the tale of how my initial idea transcended the realm of thoughts and escaped into a palpable reality that I could grasp and hold.

Check out the YouTube Video about the process here:

“Ideas are the eggs of objects” - Albert Einstein

Einstein believed that ideas are not mere abstract concepts, but rather entities that possess qualities resembling living organisms. Like ethereal beings, they glide through the realm of ideas, silently attaching themselves to unsuspecting individuals. These individuals, almost as if under the spell of a captivating parasite, find themselves compelled to channel substantial energy and resources into nurturing these ideas, bringing them to life in the physical realm.

Yeah… that was actually a theory from Joe Rogan, probably after a bit too much marijuana. Here’s the full clip!

While that idea sounds pretty wacky, it does feel like what has happened to me.

~How the Idea found Me~

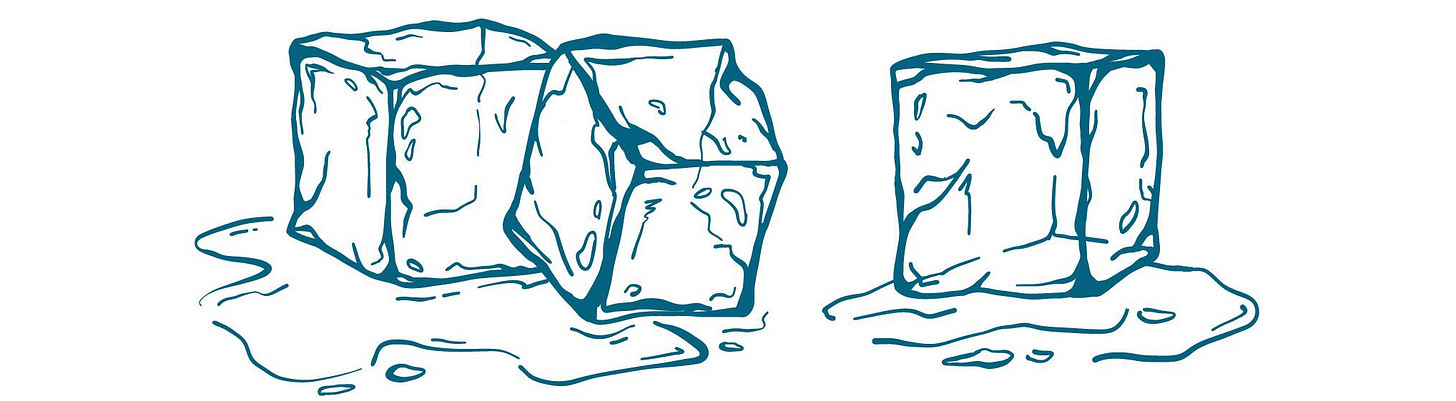

As a lifelong competitive swimmer, I know the challenges each swim season brings. When the summer swim season kicks off in late May or early June, the pool is a frigid, intimidating place. Mentally, it's a battle just to muster the courage to dive into the icy water, knowing that a grueling two-hour workout awaits.

However, as the weeks pass and we reach the peak of summer in late July or August, the pool undergoes a transformation. The once bone-chilling water now resembles that of a relaxing bath, which might sound appealing, but for swimmers, it's a double-edged sword. The warm temperatures turn what would be a tough swim workout into a truly hellish ordeal.

Amidst the scorching heat, there is one saving grace for us swimmers: our trusty water bottles. The refreshing sip of cool water provides a momentary respite from the sweltering conditions. Unfortunately, the standard Gatorade Squeeze Bottle falls victim to the relentless summer heat. Its contents change from a revitalizing stream to a lukewarm, stagnant concoction, accompanied by faint hints of plastic and chemical flavors.

So why use a Gatorade Squeeze Bottle? Connivence and speed. With a simple twitch of the hand, athletes can enjoy a steady stream of hydration without any fuss or spills. It's the ultimate hassle-free solution for staying refreshed during intense workouts.

For swimmers, the clock reigns supreme, holding absolute authority. They are perpetually challenged by its ticking hands, both in competition and training, adhering to precise intervals. Within the relentless rhythm of their sets, a mere ten-second break becomes a lifeline—a brief opportunity for swimmers to catch their breath and rehydrate. In these fleeting moments, squeezing a Gatorade Bottle offers the perfect means to replenish and rehydrate quickly, ensuring they make the most of every valuable second.

In one of those hellish swim workouts, an “idea spirit” latched itself onto my brain. Its voice was faint at first, but the message was clear. Swimmers, or any athlete plagued by the summer sun, needed a better water bottle, and I was going to be the one to make it a reality.

The Business Thought Process

I had my niche and problem, now I needed a solution.

Niche: Swimmers

Problem: Water bottles

Solution: ???

For more on how I generate business ideas, check out my post here!

The Solution: Improve the Squeezable Bottle

So there I was, twenty-one years old and freshly under the influence of this 'idea spirit'. It completed me to embark on a quest for knowledge about water bottles. I delved deep into the research, exploring insulation methods, materials, and the wide array of bottles available on the market. In no time, I transformed into a walking water bottle encyclopedia.

During the research, I stumbled upon an insulation material typically used for houses: fiberglass. This discovery would lead me down a fascinating rabbit hole, introducing me to its remarkable cousin, carbon fiber. I could use carbon fiber to create a squeezable bottle with exceptional insulation capabilities, or so I thought...

Bubbling with excitement, I dialed the number of the first company on Google that could craft Carbon Fiber prototypes. As I eagerly explained my groundbreaking idea over the phone, I could sense a mix of curiosity and confusion on the other end. Nevertheless, they offered to bring my concept to life, for the low price of $20,000.

Undeterred and inspired by countless motivational YouTube videos, I made a bold decision. Rejecting their offer, I resolved to take matters into my own hands and create the product myself. With a $400 3D printer and an additional $300 investment in carbon fiber and other necessary materials, I embarked on this entrepreneurial journey. The world was reeling from the impact of Covid-19, leaving me with ample time and zero distractions. Days turned into nights as I immersed myself in the creative process, determined to bring my genius idea to life.

I Failed Miserably.

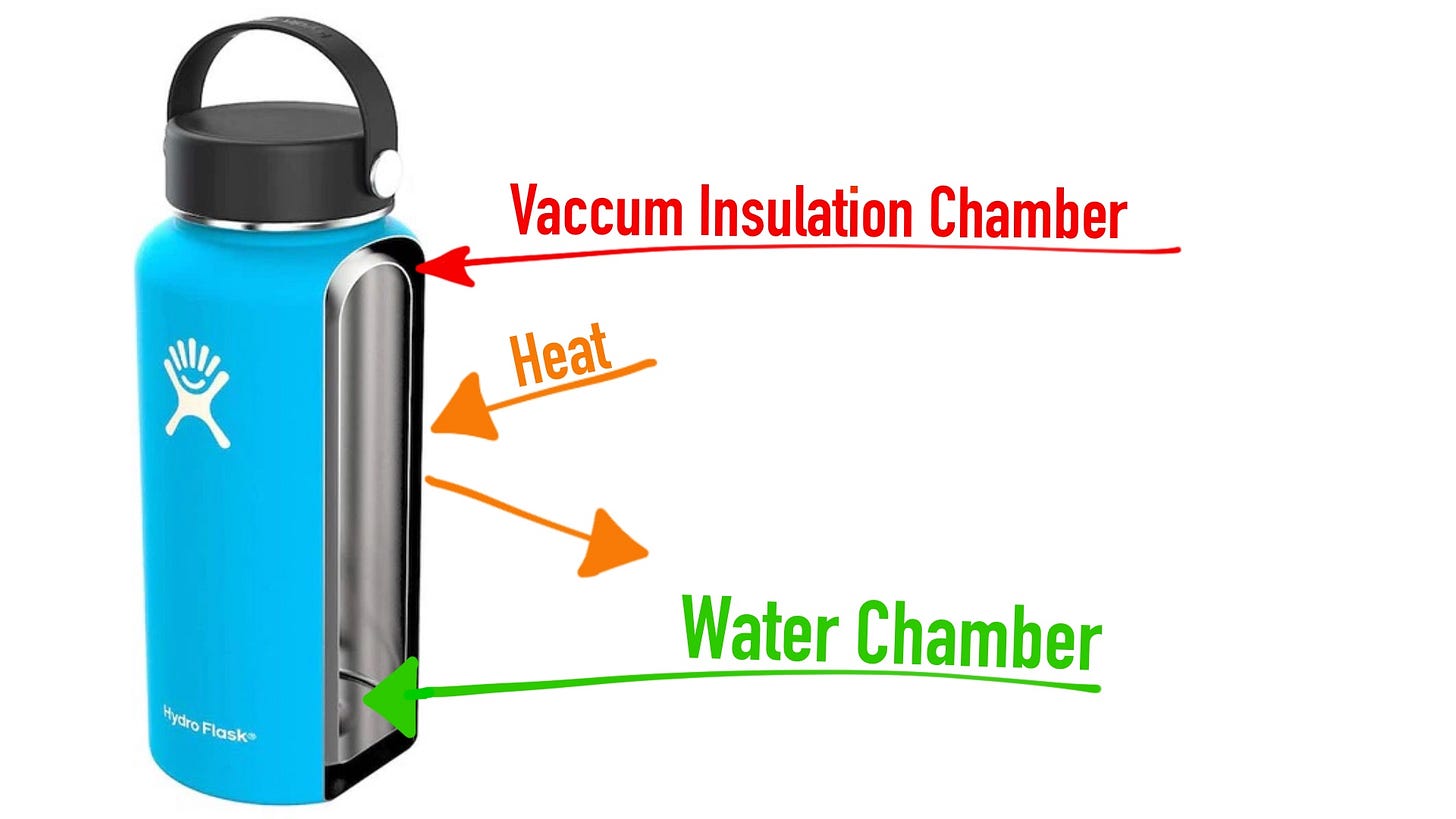

Apparently, during my quest for knowledge about water bottles, I missed a key detail. Stainless steel vacuum flasks can keep your drink ice cold for over twenty-four hours! I had assumed this amazing quality came from the steel the bottle was made from. I was dead wrong. It came from a principle called vacuum insulation.

Vacuum insulation, as used in bottles like the Hydro Flask, relies on a unique design featuring two steel layers with a void in between. This empty space, like the vacuum of space, prevents heat transfer since there is nothing for the heat to transfer onto. To maintain the integrity of the vacuum, a rigid layer such as steel is necessary to hold it in place. This makes implementing this technology into a squeezable bottle impossible because the flexibility required for squeezing would compromise the vacuum insulation. This innovative design is what enables a Hydro Flask to keep beverages cold for extended periods, even in scorching sunlight.

Dejected, I put that idea on the shelf for a few years. A few more swim seasons came and went. I tried to ignore that water bottles were poorly serving me and the other athletes, but the idea spirit wouldn’t let me forget. Suddenly, during the last few weeks of my last swim season as a college senior, I realized I needed to look at the problem backwards. If I couldn’t make squeezable bottles as insulated as stainless steel vacuum flasks, maybe I could make stainless steel vacuum flasks as quick to drink out of as squeezable bottles.

The Solution #2: Improve the Stainless Steel Insulated Flask

The market is flooded with various stainless steel water bottle caps, but one particular type stands out for its superior quick-opening and closing mechanism. I’ve named them "the pops"… because they pop open and closed. These caps excel in terms of speed and convenience. The pops are good, but not great. They can be somewhat fragile, their appearance may appear unconventional, and they lack the ability to drink from the bottle in a 360-degree fashion. These shortcomings prompted me to seek a solution that combines the best features of the pops with enhanced durability, aesthetic appeal, and the versatility to drink from any angle.

I dusted off the old 3D-printer and got back to work. I used the free program TinkerCad to start mashing shapes together. It took a few tries…

After six months of relentless dedication, I finally had something tangible in my hands—an embodiment of my idea. It can be quickly clicked open and closed, is durable, unique looking, provides drinking from ANY angle, AND can be opened with boxing gloves on… something the pop caps could only dream of.

*Patent Pending*

Although it was admittedly a crude prototype, it marked a significant milestone and served as a starting point for collaboration with a professional product designer whom I had recently hired. This physical working model became a powerful tool, allowing me to vividly convey my vision for the finished product. In a world where a picture is said to be worth a thousand words, how many words is a physical working model worth? Countless. A physical working model transcends words, encapsulating the essence and potential of my innovation.

That being said… Should I have spent six months learning how to build a 3D-printed prototype that would be heavily altered for mass production anyway? Would the time and money be better invested somewhere else? I ultimately intended to create the completed model by myself, not having to rely on a professional. I think the answer, as in most things, lies somewhere in the middle. The practice of developing my idea was useful but it dramatically lengthen the idea to the physical product phase of starting a business.

Contemplating the six-month investment I made in learning to build a 3D-printed prototype, I couldn't help but question its value. Considering that the prototype would undergo substantial changes for mass production, I wondered if my time and resources would have been better allocated elsewhere. Initially, my intention was to create the final product entirely on my own, without relying on a professional.

In hindsight, I believe the answer lies somewhere in the middle. While the practice of developing my idea and creating the prototype served as a valuable learning experience, it undeniably prolonged the transition from an idea to a fully realized physical product, which is a crucial phase in launching a business. A balance between honing my skills and leveraging the expertise of professionals would have yielded a more efficient and effective path forward.

Check out My YouTube for more!